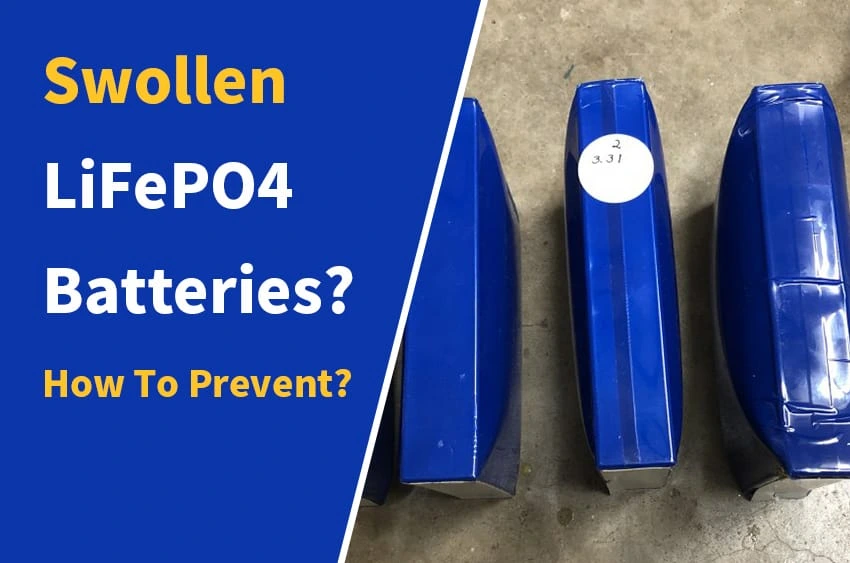

Swollen LiFePO4 batteries are the result of too much current inside a cell of the battery, which causes a build-up of heat and gas. This can be caused by overcharging, deep discharge, overheating to battery or manufacturer defects, or environmental reasons. In this article, we discuss why that happens and how you can prevent that.

LiFePO4 battery swelling is one of the important physical characteristics before LiFePO4 battery failure. Sometimes LiFePO4 batteries puff/swell up to twice their original size.

What Causes Swollen LiFePO4 Batteries?

Causes of swollen LiFePO4 batteries

- Abuse like over charge, over discharge;

- Environmental reasons like high temperature, high humidity, ultra low pressure;

- Production process reasons.

1. LiFePO4 battery swollen caused by overcharge

Overcharging will cause all the lithium atoms in the positive electrode material to run into the negative electrode material, resulting in the loss of lithium atoms in the positive electrode, which is also an important reason for the decrease in battery power. In this process, the positive electrode has fewer and fewer lithium atoms, and the negative electrode has more and more lithium atoms, which will cause the battery to bulge.

2. LiFePO4 battery swollen caused by over-discharge

LiFePO4 batteries will reversibly damage the passivation layer covering the surface of the battery after excessive discharge. The destruction of the passivation film that protects the negative electrode material will damage the negative electrode material and cause the battery to bulge.

3. The problem of production process

Lithium-ion battery bulging may be a problem in the production process of lithium iron phosphate batteries, because the electrode layer is uneven and the production process is relatively rough, resulting in battery bulging.

4. Long-term idle

If the battery is not used for a long time, swelling will also occur, because the air is also conductive to a certain extent, so the battery is placed for too long, which is equivalent to direct contact between the positive and negative electrodes of the battery, causing a chronic short circuit.

Can Swollen LiFePO4 Batteries be Replaced?

There is no doubt that the swollen LiFePO4 batteries can be replaced. But it needs to be judged according to the actual situation. At present, there are two cases of swollen LiFePO4 batteries:

One is the reversible deformation caused by changes in the positive and negative materials. Reversible deformation has always been accompanied by the cyclic charging and discharging process of lithium batteries.

The other is the irreversible deformation caused by the gas generated inside the lithium battery. Irreversible deformation occurs under abuse conditions, such as overcharge, over-discharge, and overheating.

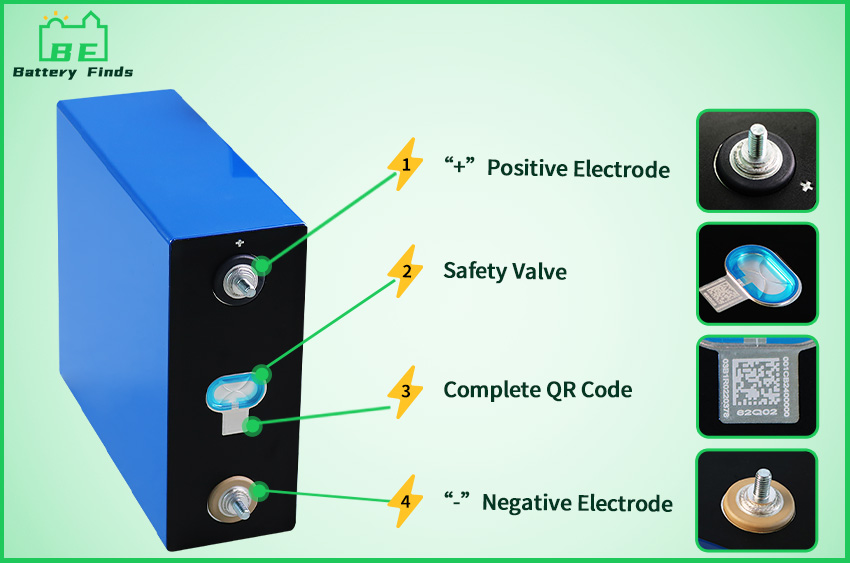

When it occurs short circuit or excess pressure in a vessel, the safety valve works. The toxic gas will be discharged in time to prevent fire disasters and other major accidents. Make the LiFePO4 battery 100% safe. Here is a picture of the LiFePO4 prismatic cells component for your better understanding.

Mildly swelling batteries can try to compress the battery or rebalance the charge to eliminate swelling. But a heavy swelling battery should only be considered to be replaced because it is very dangerous.

(Picture: LiFePO4 Prismatic Cells Component; *2: Safety Valve)

How to Prevent Swollen LiFePO4 Batteries?

To prevent the swollen LiFePO4 batteries, the most important thing is to ensure that the battery is used normally and do not use the battery illegally. For example, overcharging will not only cause bulging, but also damage the internal structure of the battery, which is a great threat to LiFePO4 battery. It is also necessary to pay attention to the maintenance of the battery terminals at ordinary times. The oxidation of the battery terminals will lead to the weakening of the performance of the battery.

The last thing is to choose a well-known brand battery provided by a reliable LiFePO4 battery supplier. Poor quality batteries are often more prone to the problem of swollen LiFePO4 batteries. Although brand batteries will be slightly more expensive, for performance and safety, the money is not necessary to save.

I had nightmares about my 16s2p 272 Ah Lishen battery (for solar) swelling, then shorting or ripping off

the terminals (screws). The busbars to connect them were (supplied by seller) were 2mm X 20mm

nickel plated Copper. They are rigid and prevent the cells from moving. So, I lossen terminals

and used long threaded rods to compress the cells together, then tightened the terminal nuts. Then I found

out about the possibility of adjacent cells shorting. So, I placed a linoleum piece of plastic between

each cell and repeated the compression procedure. Then I ran into the problem of a few busbars getting

hot during high charging (~100Amps). At first I thought the busbar was too thin. But that did not

explain why only a few got hot. So I measured the voltage drop across the battery terminal to

busbar. 50+ millivolts drop across the connections were the problem. Next I carefully polished and cleaned each terminal/busbar connection and re-compressed. That seem to solve the problem for about a month. Now I have to loosen and re-tighten (8Nm max or strip the Al threads in cell) to fix the problem every few weeks. The biggest problem is the additional voltage drop fools the BMS into thinking the cell is being over charged and shuts down the charging process prematurely. I would greatly appreciate a solution to these

problems. There is so much misinformation on the Internet. I enjoyed your articles very much.

One more thing. Some cells come with clear or blue pressure seals. What does this mean something about

the cell? Thanks in advance, Doug

I haveba swollen battery I’m charging the batteries with an epever charge controller .used the settings they recommended will never waist money these batteries again the terminal thread is soft as butter .is it a must to have bms with these batteries .

You are absolutely correct to measure voltage between the battery stud and the respective busbar. 50mV at or near full battery full load will cause quite a bit of heat. These batteries use aluminum terminals. Once the terminals are polished, they need Noalox to keep the conductivity high over time. On a mobile application (VanLife) check each terminal/ busbar connection voltage regularly anyway while discharging the battery at a significant load. Your target should be zero to 2mV. Also check your disconnect switch, and ANL fuses to fuse block similarly.