LiFePO4 battery busbars are an important accessory and an option that cannot be ignored when you DIY a LiFePO4 battery pack. Proper battery busbars are critical to improving the performance of the entire battery pack.

LiFePO4 Battery Busbars & Thick Gauge Cable, who’s the best?

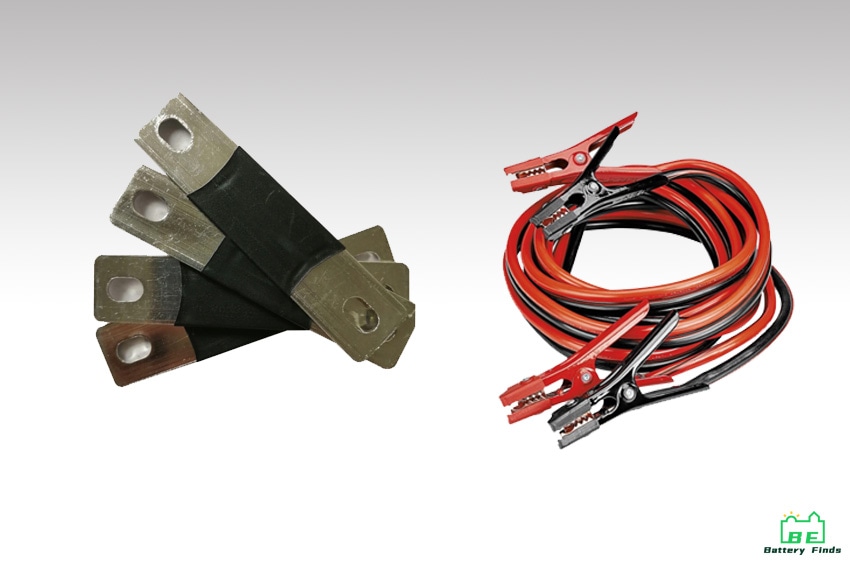

First, we need to know that to connect your LiFePO4 battery, you have two options: battery busbars or thick gauge cable. Battery busbars are circuit-connecting metal bars that are used for short-distance connections, support high-current power distribution, and are optimized for current requirements and performance specifications, which can effectively handle high current and heat dissipation. Battery busbars can be made in a variety of shapes, generally in the shape of flat bars, but also in the shape of solid rods and hollow tubes. Among them, the flat or hollow-shaped busbars are usually suitable for high current applications. The thick gauge cable can be simply understood as a thickened wire, which can provide the function of circuit connection for your LiFePO4 battery.

We generally use battery busbars to connect our cells, because busbars are more flexible, safer, and relatively low-cost, so they are the most common and popular. But some people will choose thick gauge cable for some reason.

What material are LiFePO4 Battery Busbars made of?

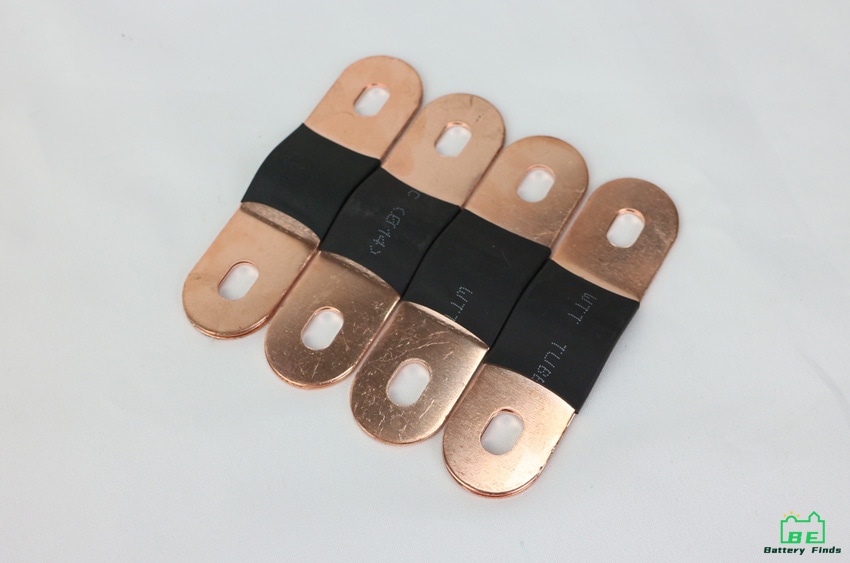

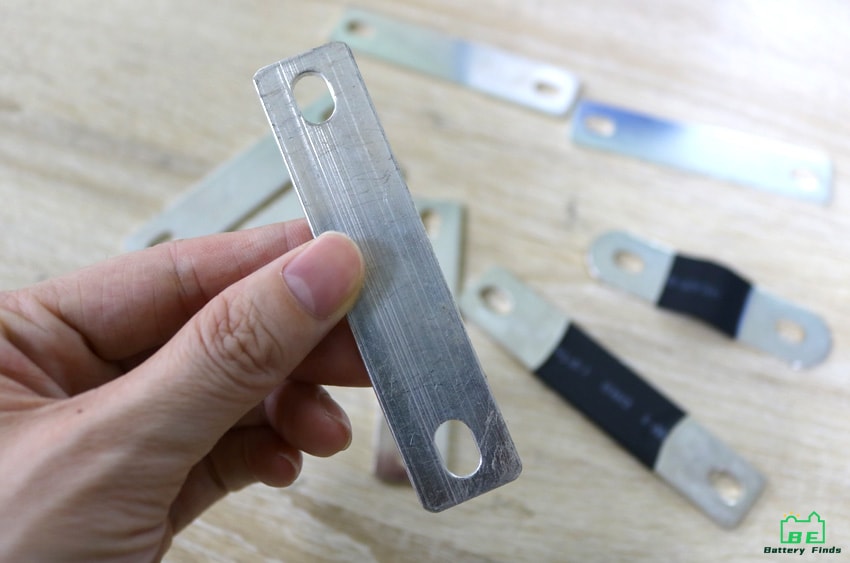

There are two main types of LiFePO4 battery busbars, copper busbars and aluminum busbars. Both materials are great for battery busbars, but there will be some differences in conductivity.

Copper has very high electrical conductivity, low electrical resistance, and high tensile strength. This has led many to believe that copper is the conductor of choice for electrical circuits. However, copper busbars generally do not expose copper directly to the air but are plated with a non-corrosive material on the surface to prevent copper oxidation.

Aluminum is another metal that conducts fairly well. However, the ductility is poor, and the conductivity cannot reach the strength of copper, but the advantage is that it is cheaper.

You can find other suitable materials for busbars in Common Conductive Metals.

How to Select the LiFePO4 Battery Busbars?

First, you need to decide which type of LiFePO4 battery busbars to use based on your circuit system. If the capacity of the battery pack is large and the requirements for electrical conductivity are relatively high, then copper busbars are the best choice.

Then you need to choose battery busbars according to the size of each cell. There are three most important factors to consider: the length, width, and thickness of the busbars.

First of all, it is necessary to determine the connection method of the cells in the circuit system. The lengths required for series and parallel are different, and the lengths required for bold or straight methods are also different. The length of the busbars must be appropriate, because too long busbars may cause some unexpected risks. In addition, the width needs to be wide enough, and the secret to maximizing battery pack performance is maximizing the contact area between the cell terminals and the busbars. And the thickness needs to be enough to support the current flow, too thin busbars can not play the best conductivity. It is worth mentioning that busbars of suitable width, length, and thickness can better match the performance of the battery pack, while busbars with excess performance are not very recommended, because busbars that exceed the internal performance of the battery pack will only cause waste.

Calculating measurements for the length, width and thickness of the battery busbars required are actually not difficult.

- Length, you need to measure the distance between the two cell terminals, and you need to reserve a little space – too compact busbars may damage the cell terminals.

- Width, you need to measure the width of the cell terminal, generally choose 3/4 width of the cell terminal as the reference width of the busbars, so as to match the cell stud.

- Thickness, this parameter means that the current, resistance, and ampacity of the battery pack must be weighed to determine how thick the busbars are needed to support the electrical load. Among them, resistance is the most important parameter, and the calculation formula of resistance is resistance (R) = resistance of the material (p) * length of material (l) / cross-sectional area of material (A).

Finally, remember that about a week after the battery pack is installed, it is necessary to double-check that all battery terminals and the busbars are still tightened, because once loose, there is a risk of causing high resistance connections, which can reduce the performance of the battery pack. At the same time, there are also some unsafe factors.

Summary

The correct selection and installation of LiFePO4 battery busbars determine the power output of your battery pack. Although choosing busbars may seem complicated, don’t worry too much. At present, most of the LiFePO4 battery wholesalers will match the most suitable busbars for the LiFePO4 batteries they sell, which can perfectly solve the related problems. There are only a few cases where you will need to make battery busbars yourself.

What about busbars with heaters?

Can you please share some information about suppliers of Busbars for LiFePO4 battery cells interconnection for Battery manufacturing.