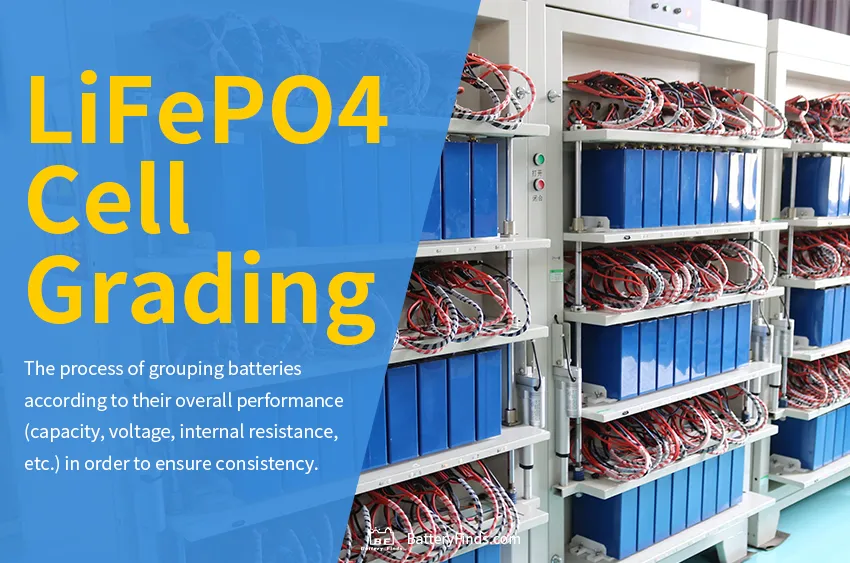

Phosphate Iron Lithium Battery (LiFePO4) Cell Grading is the process of grouping batteries according to their overall performance (capacity, voltage, internal resistance, etc.) in order to ensure consistency.

LiFePO4 Cell grading determines the quality of the battery and can be accomplished by measuring the discharge capacity during full charge. There are two explanations for cell grading.

First, during the grading process, data is collected from each detection point on the battery through computer management. The data is then analyzed to determine the size of the battery’s capacity and internal resistance, allowing the quality level of the battery to be determined. Following the initial grading, batteries should remain stationary for at least 15 days, during which time any underlying quality issues will surface.

The second explanation is that after production, lithium-ion cells may vary in capacity despite having the same dimensions. Therefore, it is necessary to charge them according to specifications, followed by discharging them at the specified current rate. The time taken to discharge the cell multiplied by the discharge current determines the cell’s capacity. Only cells that meet or exceed the specified capacity are deemed qualified, while cells that fall below the required capacity are not considered qualified. The process of selecting qualified cells through capacity testing is called cell grading.

Cell formation is a series of processing measures that stabilize the performance of the cell during the initial charge. This process includes low-current charging and discharging, as well as temperature stabilization.

The principle of cell grading for lithium-ion batteries is carried out using a formation and grading cabinet. This cabinet serves as a charger that can charge and discharge numerous batteries simultaneously. During cell grading, data is collected from each detection point on the battery via computer management. The data is then analyzed to determine the size of the battery’s capacity and internal resistance, allowing the quality level of the battery to be determined.

The cell grading process is essential as it allows batteries to be screened for quality before being used in production or sold to consumers. After cell grading, batteries are held in storage for at least 15 days to ensure any underlying issues will surface. The batteries are then re-tested to determine their capacity, and any batteries that do not meet the required capacity or have quality issues are removed from production.

By grading and grouping lithium-ion cells based on their internal resistance and capacity, the battery packs produced are more reliable, efficient, and longer-lasting. Therefore, it is essential to conduct cell grading for all lithium-ion batteries, including Phosphate Iron Lithium Batteries (LiFePO4).