Series and parallel are the connection methods of all battery cells, and all connections are based on these two connection methods. A single battery cell can play a very limited role, such as LiFePO4 battery, a single cell has only a voltage of 3.2V, and the maximum capacity generally does not exceed 350Ah, which is obviously insufficient for battery backup or energy storage equipment.

To use more power, the energy of the battery pack can only be increased by connecting the batteries in series and parallel. How to correctly use the series and parallel has also become a necessary knowledge for DIY battery equipment.

What are Series and Parallel?

In fact, series and parallel connection are not only the basic connection methods of batteries, but also the basic connection methods of all electrical components. It can be said that all circuits are inseparable from series and parallel, but to a certain extent, the series and parallel between batteries will be more familiar to us. Especially now that LiFePO4 batteries are very hot, it seems that everyone wants to learn to DIY a LiFePO4 battery pack to deal with various emergencies.

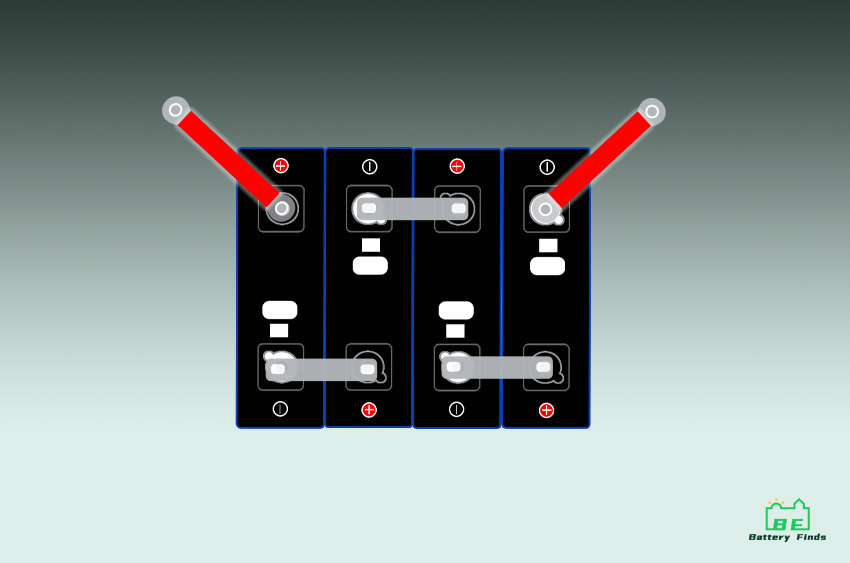

Series connection is the first connection method and the easiest way to understand. It only needs to connect the negative electrode of one LiFePO4 battery cell to the positive electrode of another LiFePO4 battery cell, even if it is connected in series. In the same way, more cells can be connected, just remember to connect the positive and negative poles of the LiFePO4 battery at the beginning and the end at the end.

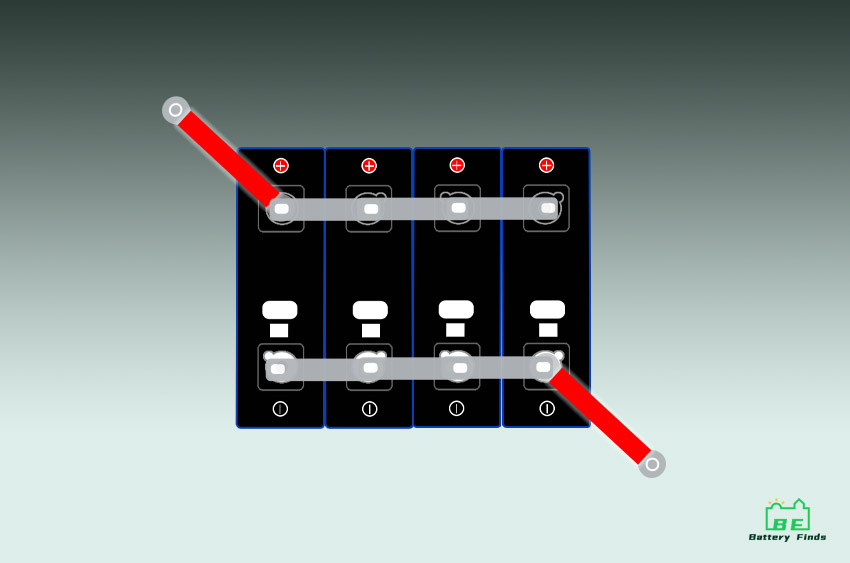

Parallel connection is another connection method, which is slightly different from the series connection. Parallel connection requires connecting the positive pole of one LiFePO4 battery cell to the positive pole of another LiFePO4 battery cell. In the same way, more cells can be connected, just remember to connect the positive and positive (or negative and negative) of the LiFePO4 battery at the end.

However, there is often not only one of series or parallel in a circuit. Series and parallel will appear together in the circuit because series or parallel alone will not achieve our needs. Combining the two connections makes the battery that works best for us.

In LiFePO4 battery DIY, for convenience, we generally record the series and parallel connection of battery packs with abbreviations. “S” means series connection, and “P” means parallel connection. For example, 16 LiFePO4 battery cells, 8 in series and 2 in parallel, we will label as “8S2P” devices, or “2P8S” devices.

What are the pros and cons of Series and Parallel?

Series:

The effect of the series connection is to allow the voltage in the LiFePO4 battery pack circuit to rise while the capacity remains the same. For example, 8 3.2V 100Ah LiFePO4 batteries can be obtained by only connecting them in series to obtain a 24V 100Ah LiFePO4 battery pack.

The advantage of series connection is that the voltage of the battery pack can be increased to meet the system requirements of 12V/24V/48V. At present, many electrical appliances have certain requirements for voltage, and if the voltage is too low, some electrical appliances cannot run smoothly. And the lower current can also ensure that the safety of the battery pack will be improved. But the disadvantage is that the requirements for each cell in the series are relatively high. If one of the cells is damaged, the voltage of the entire battery pack will drop, resulting in some unexpected situations. Although LiFePO4 battery safety is really good, inevitably there may be some over-discharge problems.

Parallel:

The effect of paralleling is to allow the capacity in the LiFePO4 battery pack circuit to go up while the capacity remains the same. For example, 8 3.2V 100Ah LiFePO4 batteries can be obtained by only connecting them in parallel to obtain 3.2V 800Ah LiFePO4 batteries.

The advantage of parallel connection is that the capacity of the battery pack can be increased so that the battery pack that meets the voltage requirements can have greater power reserve capacity through parallel connection. And it will be safer to discharge in parallel, even if there is a problem with one cell, it will not affect the circuit as seriously as in series. The disadvantage of parallel connection is that it will restrict the performance of the battery pack to a certain extent.

Of course, in practice, series and parallel appear at the same time, and the pros and cons of the two connection methods can be effectively complemented, thus becoming a LiFePO4 battery pack worthy of our trust. It should be noted that when we DIY batteries, we should try to choose LiFePO4 batteries with good consistency, and compress the LiFePO4 batteries to ensure the performance of the battery pack.

Summary

Series and parallel connection is an indispensable part of LiFePO4 battery DIY, if you are considering building your own LiFePO4 battery pack, then series and parallel connection is the knowledge that must be learned thoroughly.

I am confused over here. If four 12v 150Ah battery connected in series will have 48v and 150Ah capacity. In the backup calculation ,lets assume, i have 500w consumption , the back up hours will be (48v*150Ah)/500= 14.4hrs backup

And we connect in parallel (12v* 600Ah)/500= 14.4hrs backup.

So is this same?? In both the case i get the same output. So what makes the difference over here

Hi John. You are correct, 12V 600Ah provides the same amount of energy storage as 48V 150Ah.

The difference here is that 12V and 48V choose different wire sizes, larger amperage tends to require larger wires to keep the system safe, since more current through the wire means more resistance and more heat through.

Thanks for the info.

I gather from this that building a battery with larger capacity is best done from cell level.

To get 12.8 volts at 400Ah the configuration would be 4s4p of 8 x 100Ah cells.

Use an active balancer and keep voltage at or below 14.6 vols. Not using BMS

Compared to using 4x 12.8 volt 100Ah batteries in parallel.

So fighting 4xBMSes

Like to hear your thought on this.

Thanks

Otto

You are correct that building a battery with larger capacity is typically best done from the cell level. Your suggested configuration of 4s4p with 16 x 100Ah cells would provide a total capacity of 400Ah at 12.8 volts. Using an active balancer and keeping the voltage at or below 14.6 volts is recommended to ensure the safety and longevity of the battery.

Managing multiple BMSes can add complexity to the system. However, using parallel connections can offer some benefits such as redundancy, higher output current, and fault tolerance. Ultimately, the decision to use series or parallel connections depends on your specific application requirements and the trade-offs between factors such as cost, complexity, safety, and performance.

Correction.. 4s4p 16 x 100Ah cells. sorry

Otto

I want to get a knowledge of how to connect my 3.2v of 200ah battery to get 48v of 200ah. I want to know how to connect it and how many do i need. Thanks

Hi, Norbert

To create a 48V(51.2V) battery pack with a total capacity of 200Ah using 16 3.2V 200Ah LFP cells, you will need to connect the cells in a 4S4P configuration.

Among the different LiFePO4 pack configurations, both a 15-cell 48V pack and a 16-cell 51.2V pack are commonly used. A 16-cell LiFeP04 51.2V pack offers superior performance compared to that of a 15-cell 48V pack with the same grade cells as the 16-cell pack. Therefore, we recommend using 16 cells to assemble a 51.2V200Ah system.

51.2V (16 x 3.2V) 200Ah | 10.24 kWh

48V (15 x 3.2V) 200Ah | 9.6kWh

◆ Materials:

• 16 x 3.2v LiFePO4 prismatic 200ah cells

• 1 x 200Amp 16S DALY Smart BMS

• 1 x 16S BMS cable

• 15 x Copper Bus Bars

• 17 x Ring Terminal Connectors

• 32 x 6M nuts

• 5A Parallel Module (Optional)

• 1A Active Balancer (Optional)

• Epoxy Board, Fish Paper, etc.

◆ Tool: Spot Welder, Soldering Iron, Wire Cutter, Multimeter, etc.

◆ Here are the steps to connect the cells:

Connect four cells in series to create a 12.8V pack:

[Cell1+] —- [Cell2-] —- [Cell2+] —- [Cell4-]

Repeat step 1 three more times to get four 12.8V packs.

Connect the four 12.8V packs in parallel:

[Pack1+] —- [Pack2+] —- [Pack3+] —- [Pack4+] —- [Pack1- Pack2- Pack3- Pack4-]

This will give you a 48V battery pack with a total capacity of 200Ah.

Please Note: Make sure you use a BMS (Battery Management System) with a temperature sensor when connecting in series to ensure safety and longevity.

If you have any questions, please feel free to contact us.

Best Regards,

BatteryFinds

I have 2 KW 3 Phase load, But we wants 3 days Autonomy , we have considered 12 Hours working , approximately 134kwhr storage, What capacity Inverter I should chose to Charge the batteries as well keep the autonomy and what configuration Series , Parallel Batteries I can chose with least BMS and Optimum combination will appreciate your feed back

Hi,Aditya

To determine the capacity of the inverter and the configuration of batteries for your specific requirements, we’ll need to consider a few factors.

1. Calculating the battery capacity:

Given a 12-hour working day and a 2 kW load, the total energy consumption per day is:

2 kW * 12 hours = 24 kWh

To achieve a 3-day autonomy, we multiply the daily energy consumption by the number of days:

24 kWh * 3 = 72 kWh

Therefore, you’ll need a battery storage capacity of approximately 72 kWh to meet your requirements.

2. Selecting the battery configuration:

To determine the battery configuration, we need to consider the voltage and capacity of the individual batteries. Let’s assume you have access to 12V batteries with a capacity of 100 Ah.

To calculate the number of batteries required, convert the total required capacity to amp-hours (Ah):

Required capacity = 72 kWh = 72,000 Wh

Assuming a 12V battery system, the capacity in Ah is:

Capacity in Ah = 72,000 Wh / 12V = 6,000 Ah

With 100 Ah batteries, you’ll need:

Number of batteries = 6,000 Ah / 100 Ah = 60 batteries

Now, you have two options for configuring the batteries: series or parallel.

Series configuration:

In a series configuration, the voltage adds up, while the capacity remains the same. To calculate the voltage:

Total voltage = Number of batteries * Individual battery voltage

Total voltage = 60 batteries * 12V = 720V

Parallel configuration:

The voltage remains the same in a parallel configuration, while the capacity adds up. To calculate the capacity:

Total capacity = Number of batteries * Individual battery capacity

Total capacity = 60 batteries * 100 Ah = 6,000 Ah

You can choose either a series or parallel configuration based on the requirements of your inverter and charging system.

3. Determining the inverter capacity:

To select an appropriate inverter, consider the power requirements of your load, the charging efficiency, and any other additional loads you might have.

Since you have a 2 kW (or 2,000 W) load, you’ll need an inverter that can handle this power. To provide some headroom, you might consider selecting an inverter with a capacity slightly higher than the load requirement, such as a 2.5 kW or 3 kW inverter.

Additionally, ensure that the inverter has the capability to charge the batteries efficiently, considering any losses in the charging process. Consult the specifications of the inverter to confirm its charging capacity.

4.Battery Management System (BMS):

The choice of BMS depends on the battery chemistry you select. Different battery chemistries have specific BMS requirements to ensure safe and optimized operation. Consult with the battery manufacturer or a specialist to determine the appropriate BMS for your chosen batteries.

Please note that the above recommendations are for guidance only and it is recommended to consult a professional or an expert in the field of energy storage systems to ensure the best and safe configuration for your specific needs.

Best Regards

BatteryFinds Team

If I just wanted to connect two LiFePo4 batteries in series for discharging only, each with their own BMS, to increase the output voltage, would that be a simple thing to do? As I understand, issues may occur primarily during charging. So if I would charge the two batteries separately and just connect them in series when I need more voltage, would that be a simple thing to do, or am I overlooking something? Many thanks!